We begin by understanding our customers’ unique needs and challenges. This helps us recommend the most suitable material handling equipment for their operations.

learn more

At Middle Tennessee Rack we provide a comprehensive range of services to ensure a seamless experience for our customers, from the initial sale to the final installation.

In essence, we are committed to providing our customers with end-to-end solutions in material handling, ensuring a perfect sale and a perfect installation.

We begin by understanding our customers’ unique needs and challenges. This helps us recommend the most suitable material handling equipment for their operations.

learn more

We offer a wide variety of high-quality material handling equipment. Our knowledgeable sales team guides customers through the selection process, ensuring they make the perfect purchase.

learn more

We ensure timely and safe delivery of the purchased equipment to the customer’s location.

learn more

Our team of skilled technicians handles the installation process. They ensure that the equipment is perfectly set up and ready for operation.

learn more

We provide comprehensive training to the customer’s staff to ensure they can operate the equipment safely and efficiently.

learn more

We offer robust after-sales support, including maintenance and repair services, to ensure the equipment continues to operate at peak performance.

learn more

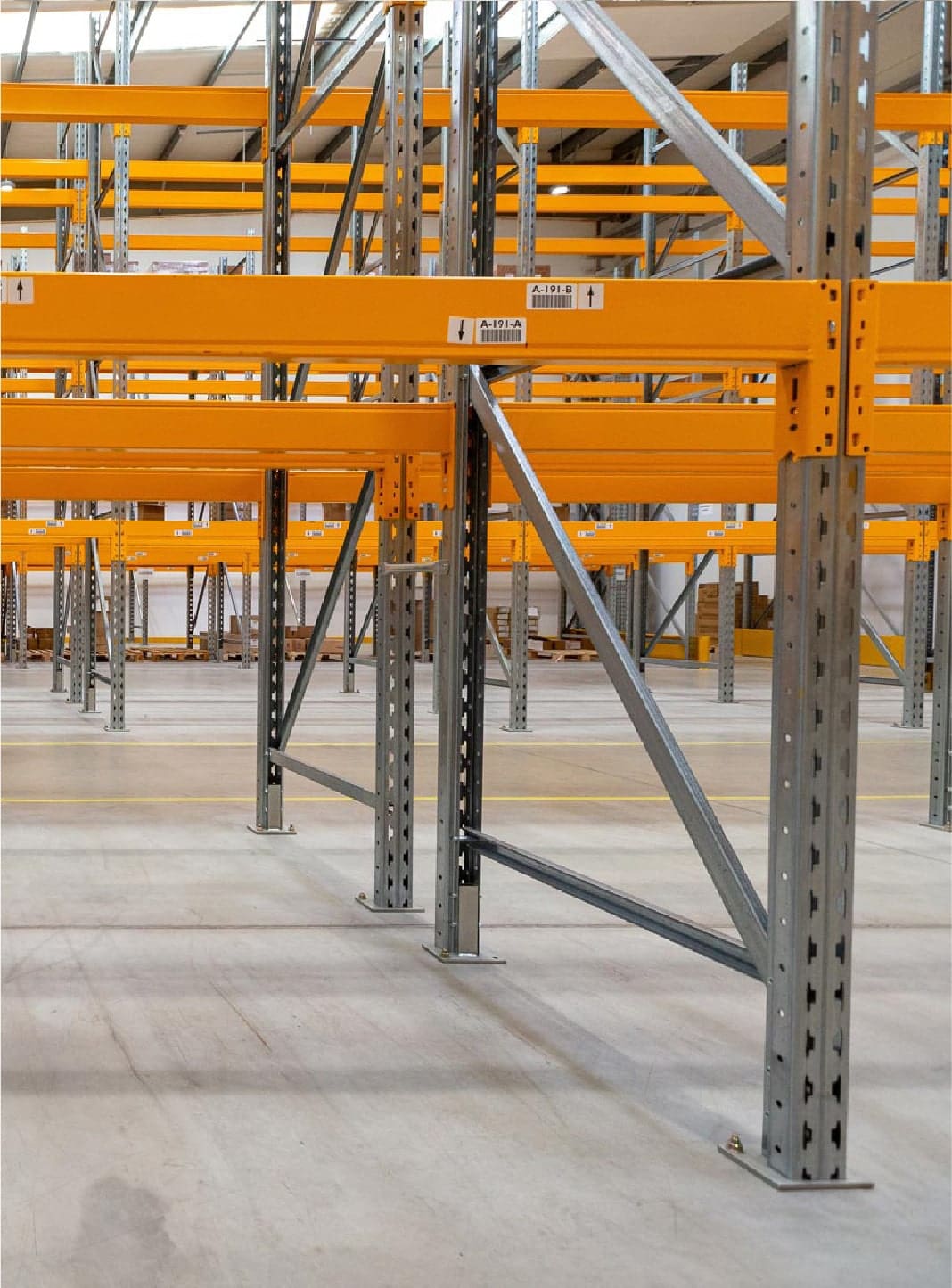

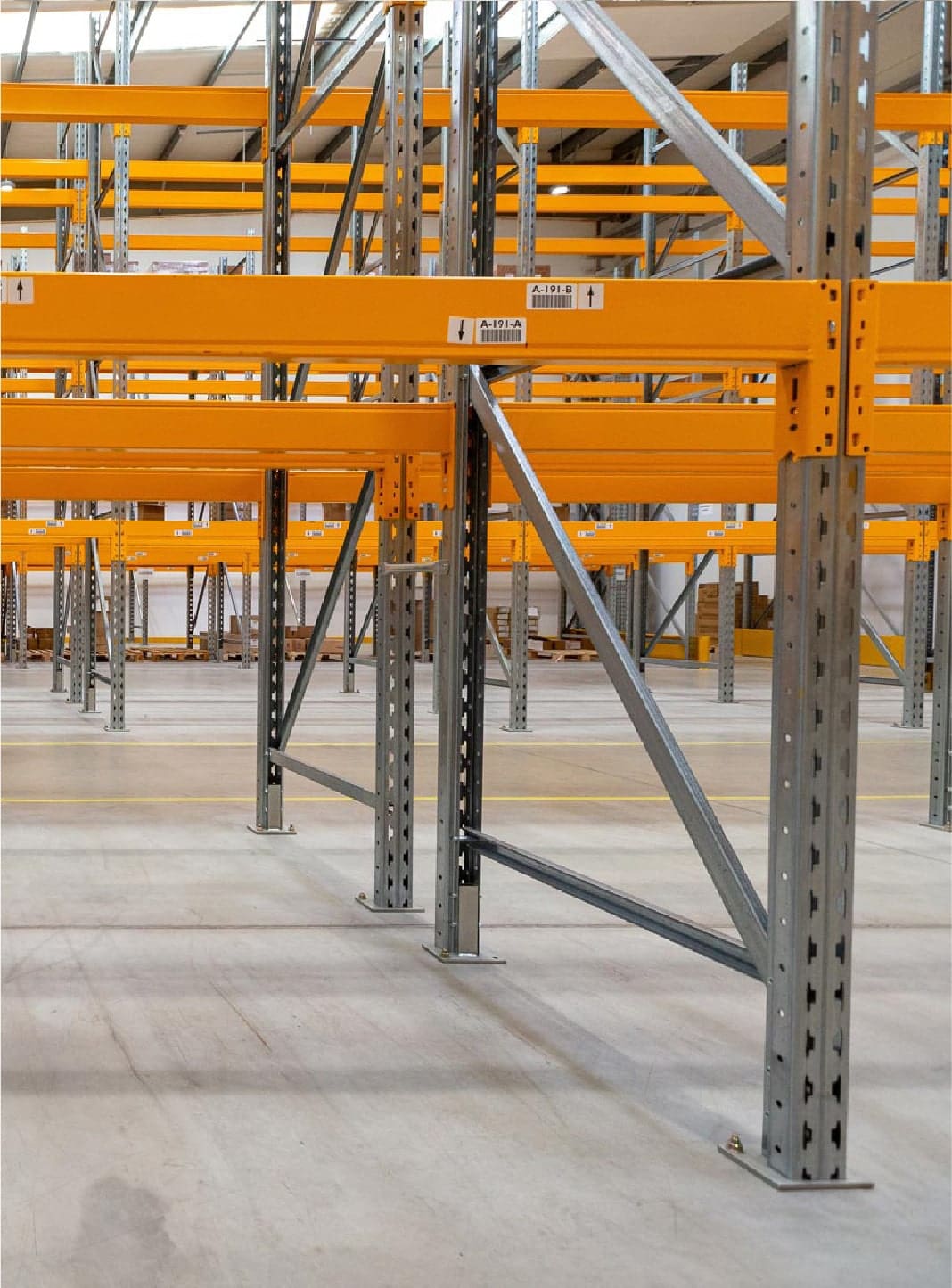

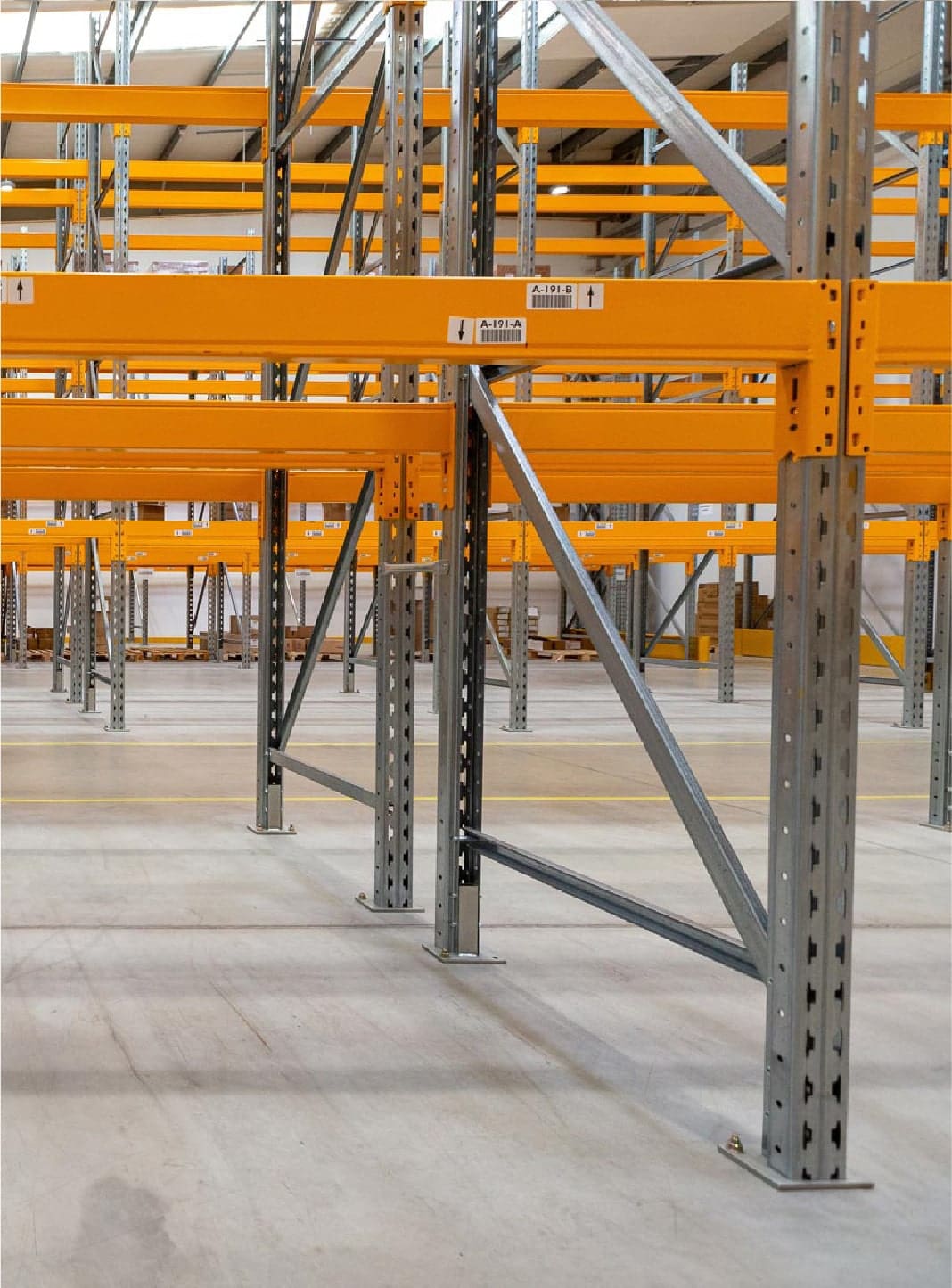

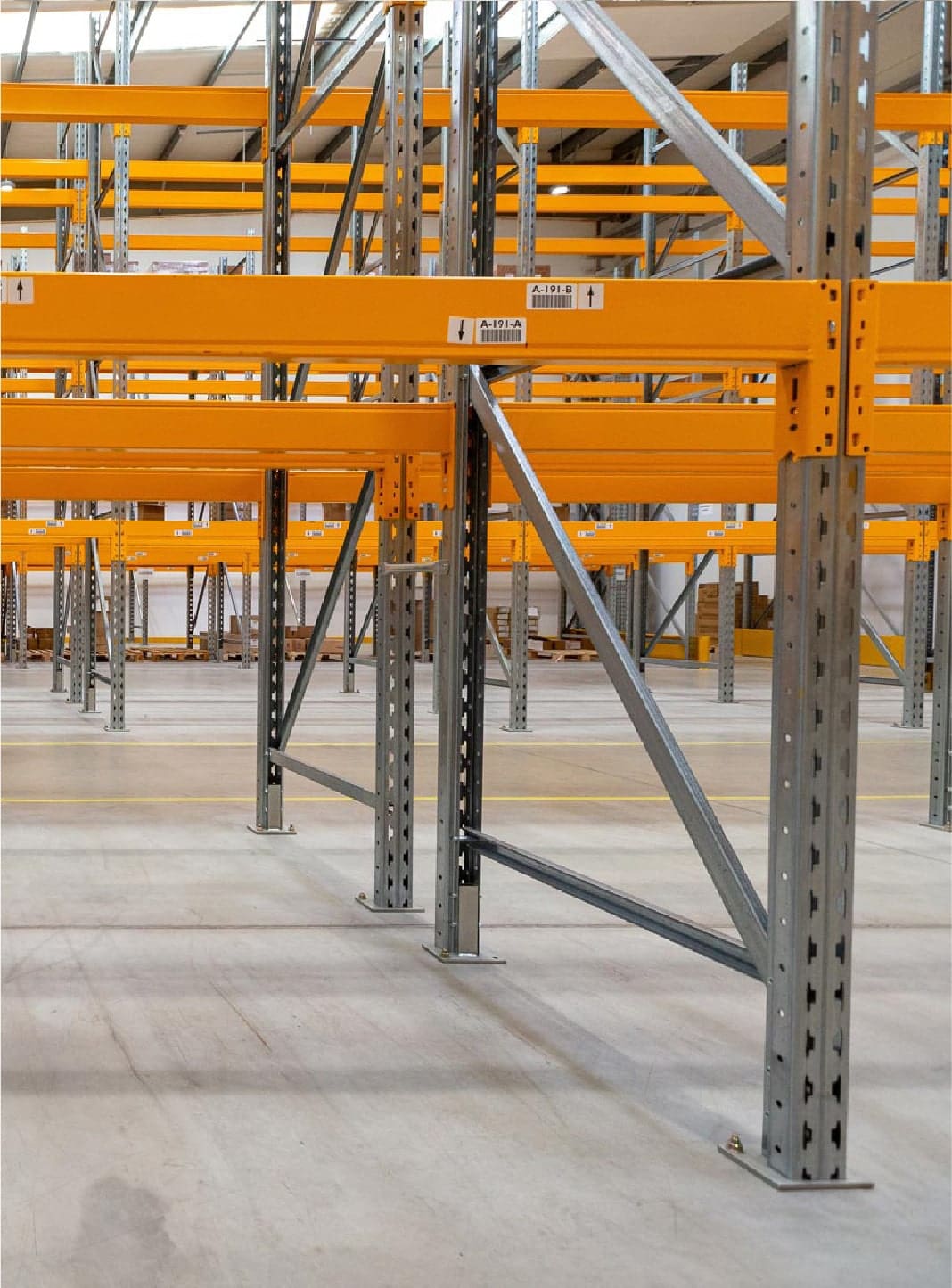

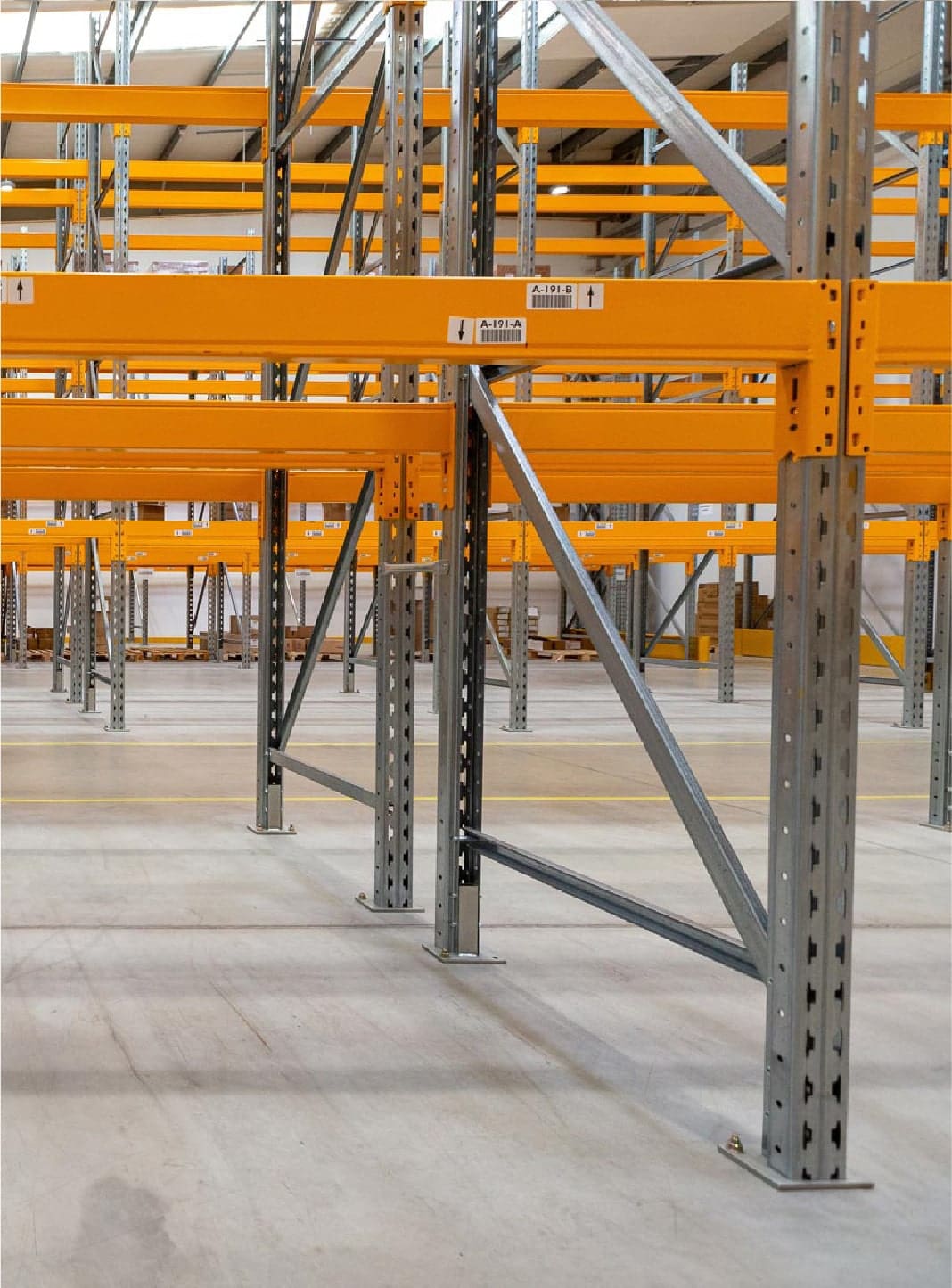

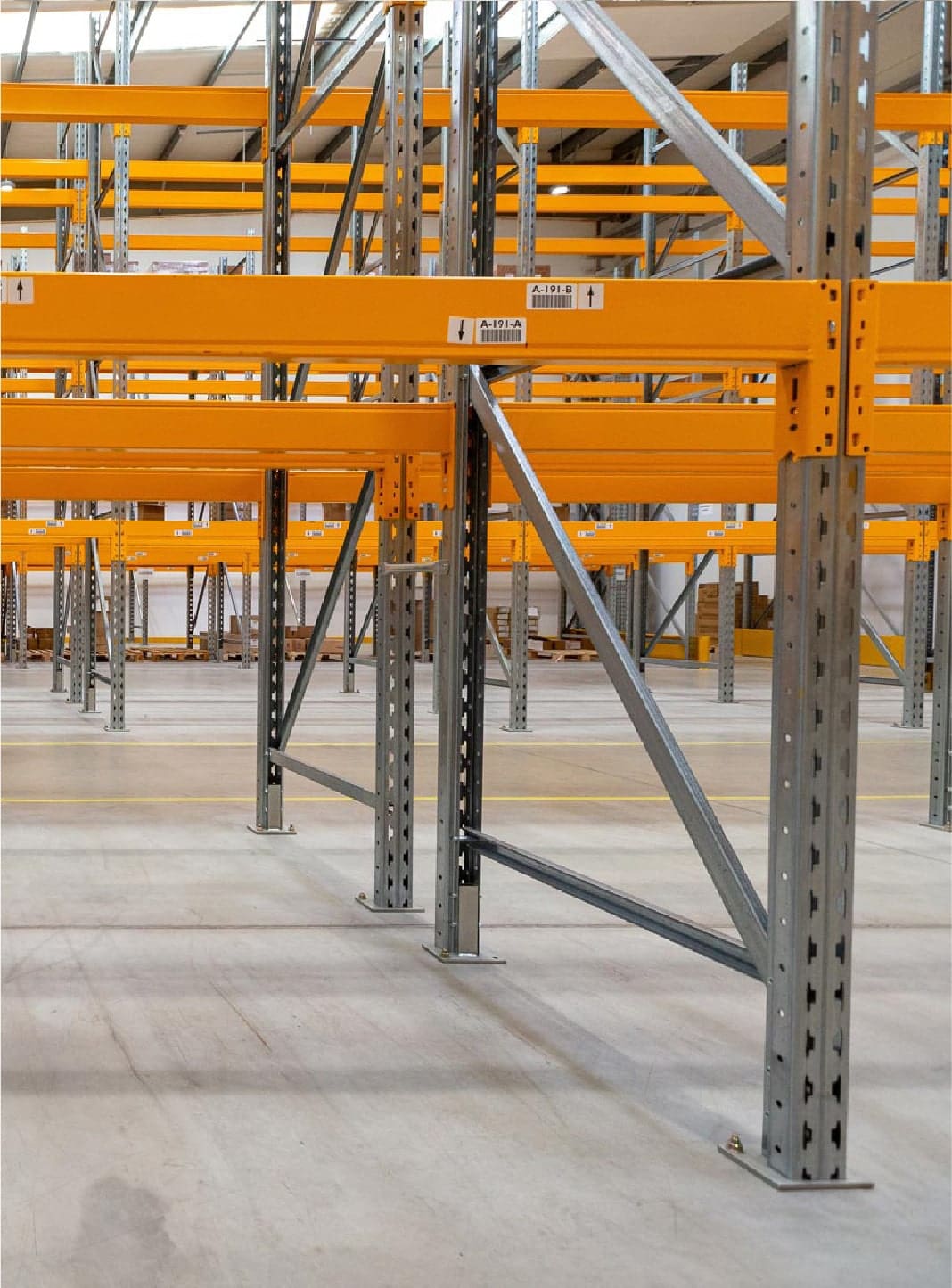

It provides direct access to every pallet in storage, making it ideal for operations with a high number of SKU counts requiring quick product accessibility.

learn more

This system is ideal for high-capacity operations with many product types or variations.

learn more

Selective pallet racking maximizes the use of vertical space to help improve rack management.

learn more

There are two primary types of selective pallet rack systems: Single Deep Selective Pallet Racks and Double Deep Pallet Racks.

learn more

The variety of accessories and configurations available allows you to adapt the racking to any type of load, both in terms of weight and volume.

learn more

They offer a more affordable solution, freeing up your budget for other business enhancements.

learn more

These systems are often simpler to assemble, saving you time and effort.

learn more

Choosing used systems contributes to environmental sustainability by extending the life of existing materials and reducing waste.

learn more

They can enhance your warehouse’s operational efficiency.

learn more

Drive-in racking systems can be placed against a wall or a corner to maximize space in your warehouse. If your needs change, a drive-in system can be converted into a drive-through system.

learn more

There are two primary types of drive-in racking systems: Single Entry and Double Entry.

learn more

One essential accessory is the pallet rack safety netting, designed to prevent products from falling off the racks, ensuring a safe working environment.

learn more

To maximize storage space, many warehouses utilize pallet rack dividers and decking accessories.

learn more

Pallet racking accessories are also designed to accommodate specific types of goods.

learn more

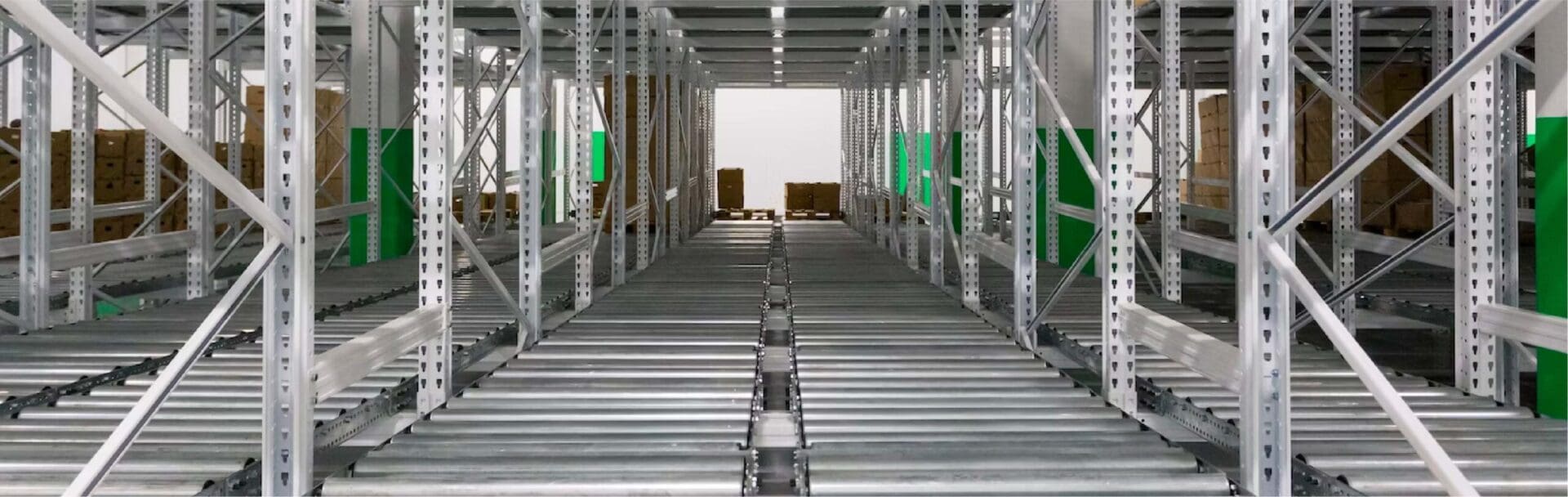

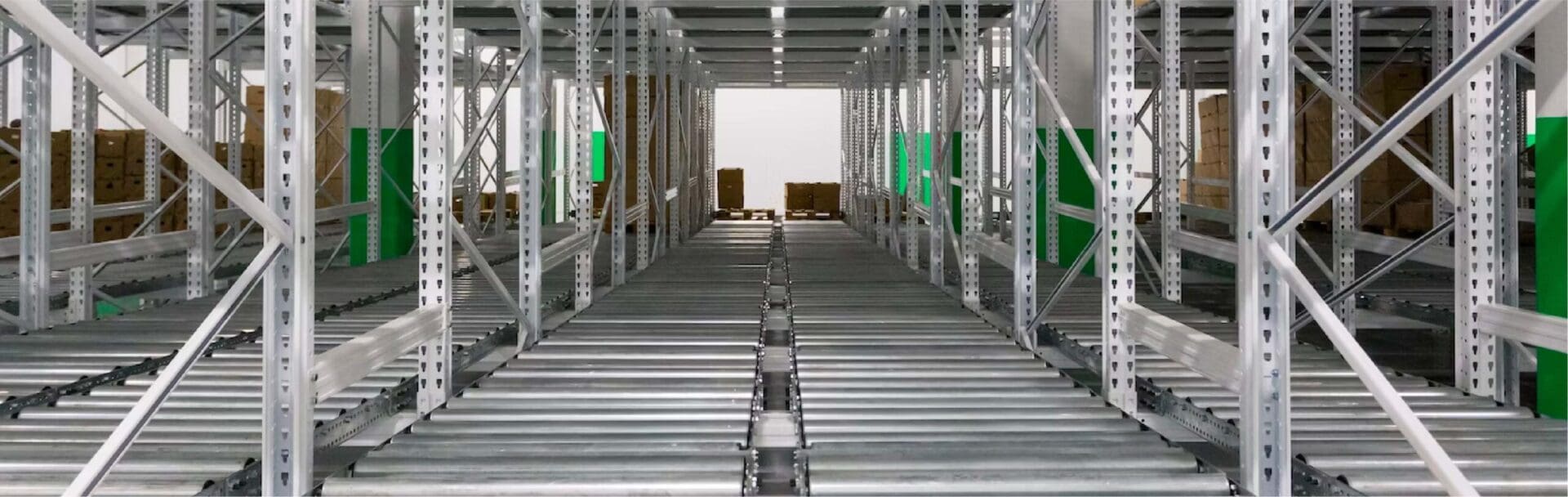

Carton flow racking is a gravity-based storage solution that stores products on inclined shelves, improving warehouse productivity, space optimization, and inventory management!

learn more

Custom pallet racks offer a tailored solution for businesses seeking to optimize their warehouse or storage facility.

learn more

The crews work fast and efficiently to install a variety of pallet racking systems, custom fit to the required area.

learn more

By properly installing the racking system, the crews help businesses make better use of their vertical space, which can significantly increase storage density.

learn more

The crews are skilled in installing various types of racking systems, allowing businesses to choose the most suitable system for their specific needs.

learn more

The crews can also dismantle and reconfigure the racking system as per the changing needs of the business.

learn more

Proper installation and dismantling by professional crews ensure the safety of the warehouse staff.

learn more

By optimizing the storage space and improving the efficiency of warehouse operations, the crews help businesses lower their total cost of ownership.

learn more

We begin by understanding our customers’ unique needs and challenges. This helps us recommend the most suitable material handling equipment for their operations.

learn more

We offer a wide variety of high-quality material handling equipment. Our knowledgeable sales team guides customers through the selection process, ensuring they make the perfect purchase.

learn more

We ensure timely and safe delivery of the purchased equipment to the customer’s location.

learn more

Our team of skilled technicians handles the installation process. They ensure that the equipment is perfectly set up and ready for operation.

learn more

We provide comprehensive training to the customer’s staff to ensure they can operate the equipment safely and efficiently.

learn more

We offer robust after-sales support, including maintenance and repair services, to ensure the equipment continues to operate at peak performance.

learn more

It provides direct access to every pallet in storage, making it ideal for operations with a high number of SKU counts requiring quick product accessibility.

learn more

This system is ideal for high-capacity operations with many product types or variations.

learn more

Selective pallet racking maximizes the use of vertical space to help improve rack management.

learn more

There are two primary types of selective pallet rack systems: Single Deep Selective Pallet Racks and Double Deep Pallet Racks.

learn more

The variety of accessories and configurations available allows you to adapt the racking to any type of load, both in terms of weight and volume.

learn more

They offer a more affordable solution, freeing up your budget for other business enhancements.

learn more

These systems are often simpler to assemble, saving you time and effort.

learn more

Choosing used systems contributes to environmental sustainability by extending the life of existing materials and reducing waste.

learn more

They can enhance your warehouse’s operational efficiency.

learn more

Drive-in racking systems can be placed against a wall or a corner to maximize space in your warehouse. If your needs change, a drive-in system can be converted into a drive-through system.

learn more

There are two primary types of drive-in racking systems: Single Entry and Double Entry.

learn more

One essential accessory is the pallet rack safety netting, designed to prevent products from falling off the racks, ensuring a safe working environment.

learn more

To maximize storage space, many warehouses utilize pallet rack dividers and decking accessories.

learn more

Pallet racking accessories are also designed to accommodate specific types of goods.

learn more

Carton flow racking is a gravity-based storage solution that stores products on inclined shelves, improving warehouse productivity, space optimization, and inventory management!

learn more

Custom pallet racks offer a tailored solution for businesses seeking to optimize their warehouse or storage facility.

learn more

The crews work fast and efficiently to install a variety of pallet racking systems, custom fit to the required area.

learn more

By properly installing the racking system, the crews help businesses make better use of their vertical space, which can significantly increase storage density.

learn more

The crews are skilled in installing various types of racking systems, allowing businesses to choose the most suitable system for their specific needs.

learn more

The crews can also dismantle and reconfigure the racking system as per the changing needs of the business.

learn more

Proper installation and dismantling by professional crews ensure the safety of the warehouse staff.

learn more

By optimizing the storage space and improving the efficiency of warehouse operations, the crews help businesses lower their total cost of ownership.

learn more